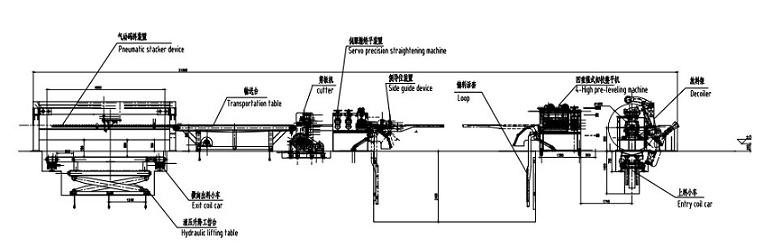

Coil Cutting Machine

the cutting process is used for uncoiling, straightening, gauging, crosscutting to length and stacking work. The cut to length line for sale can make sure of accurate feeding and shearing.▷ Cut to Length Line | Cut to Length Steel LOTOS design 2022 ◁ is controlled by the PLC system or manually as required by the customer. It has PLC controlled single shaft feeder, the information of length, shearing numbers, and speed. When the needed shearing number is reached the line can stop automatically. The line speed can be adjusted. It has a gauge with high precision, and the whole line can work automatically and operate easily thereby producing smooth sheets.

Contact us for the best cut to length line machine. LOTOS can be best cut to length line manufacturers for you. Best After-sales Service. Specialized Manufacturer Of High-Speed Slitting Machine, With 10 Years Experience. Strict Quality Control. Our steel Cut-To-Length Lines include :

cut to length machine sheet metal

- Light Gauge Cut-To-Length Lines

- 0.2 – 2 mm (1600 mm) Automatic Cut-To-Length Line

- 0.2 – 2 mm (1350 mm) Automatic Cut-To-Length Line

- 0.3 – 3 mm (1600 mm) Automatic Light Gauge Cut-To-Length Line

- 0.3 – 3 mm (1800 mm) Automatic Light Gauge Cut-To-Length Line

- 0.2 – 2 mm (1800 mm) Stainless Steel High Precision Coil cut to length line

- 0.2 – 2 mm (2100 mm) SS High Precision steel coil cutting machine

- (1600 mm) 0.2 – 3 mm 6 Layer leveling Steel Cutting line

- 0.2 – 2 mm (1800 mm) 6 Layer leveling Steel Cutting line

- Heavy Gage Cut-To-Length Lines

- 2 – 2 mm (1600) Automatic Heavy Gage Cut-To-Length Lines

- 2 – 4 mm (1800) Simple Heavy Cut-To-Length Lines

- 3 – 6 mm (1600) Semi-Automatic cut to length line machine

- 3 – 6 mm (1800) Semi-Automatic metal cut to length line machine

- 4 – 10 mm (1350) Automatic cut to length line machine

- (1600) 4 – 10 mm Automatic cut to length machine

- 4 – 10 mm (1850) Automatic cut to length machine