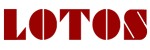

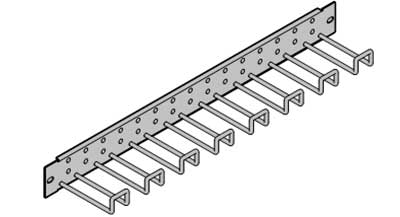

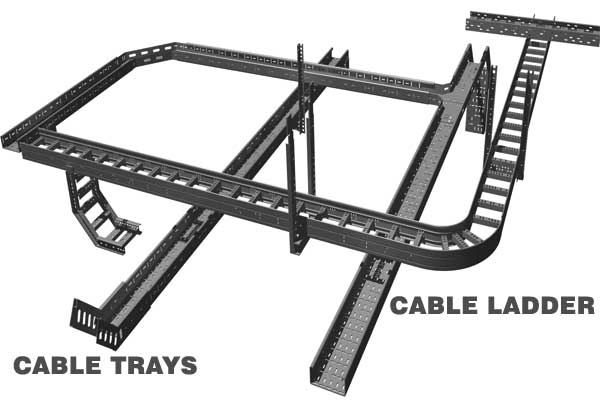

1. Ladder Cable Tray:

- Solid side rail protection and system strength with smooth radius fittings and a wide selection of materials and finishes.

- maximum strength for long-span applications with standard widths of 150, 300, 450, 600, 750, and 900 millimeters.

- standard depths of 50, 75, 100, 125, and 150 millimeters.

- the standard lengths of 3 to 6 meters.

- the rung spacing of 150, 225, 300, and 450 millimeters.

- A ladder cable tray is generally used in applications with intermediate to long support spans, 3 meters to 6 meters.

What types of Cable trays are available?

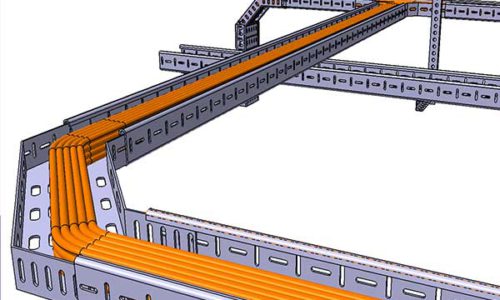

2. Solid Bottom Cable Tray:

- Non-ventilated continuous support for delicate cables with added cable protection available in metallic and fiberglass.

- Solid bottom metallic with solid metal covers for non-plenum-rated cable in environmental air areas.

- standard widths of 150, 300, 450, 600, 750, and 900 millimeters.

- the standard depths of 75, 100, 125, and 150 inches

- standard lengths of 3, 6, meters Solid Bottom cable tray is generally used for minimal heat generating Electrical or telecommunication applications with short to intermediate.

3. Trough Cable Tray:

- Moderate ventilation with added cable support frequency and with the bottom configuration providing cable support every 4 inches. Available in metal and nonmetallic materials.

- standard widths of 150, 300, 450, 600, 750, 900 millimeters

- the standard depths of 75, 100, 125, and 150 millimeters.

- standard lengths of, 3000, 6000 millimeters.

- fixed rung spacing of 100 millimeters on center Trough cable tray is generally used for moderate heat generating applications with short to intermediate support spans of 0.6, 3, 6 meters.

4. Channel Cable Tray:

- economical support for cable drops and branch cable runs from the backbone cable tray system.

- the standard widths of 75, 100, and 150 millimeters in metal systems and up to 200 millimeters in nonmetallic systems.

- standard depths of 30 to 50 millimeters in metal systems and 25, 30, 40, and 50 millimeters in nonmetallic systems.

- the standard length of 3, 4, and 6 meters Channel cable trays are used for installations with limited numbers of tray cables when the conduit is undesirable. Support frequency with short to medium support spans of 1.5 to 3 meters.

cable trunking machine

Cable trunking use to protect cables from hurt.in fact, Cable Trunking and protect your electrical cables from damage. Trunking is usually square or rectangular in shape and provides easy access to the cable when needed via a hinge or slide system.

7. Perforated Type Cable Tray

- the Perforated Type Cable Trays have uniform holes and are suitable for cables that require both a degree of protection from external damages and ventilation. These are made from galvanized iron and mild steel.

Perforated Cable Tray Machine

nonetheless, We offer a wide range of perforated cable trays machines As per the client’s requirements, we can customize our perforated cable tray roll forming machine. perforated cable trays are offered in different types, generally, make in mild steel.

so that, A cable tray is a unit or assembly of units or sections and associated fittings forming a rigid structural system. punching tray used to securely fasten or support cables and raceways. In fact, LOTOSFORMING Produce Cable Tray Roll Forming Machine that this machine use for producing perforated cable trays profile.LOTOS can produce the following machine:

- Cable tray production line

- perforated cable tray forming machine

- ladder systems roll forming machine

- Wire Mesh Cable Tray rolling machine

- Wire Basket Cable Tray roll forming machine

- Cable Bus Duct machine

Din rail channel machine

A DIN rail functions as a mechanical support structure for various types of small electrical components. A DIN rail is a metal rail of a standard type widely used for mounting circuit breakers and industrial control equipment inside equipment racks.