LOTOS Manufacturing is one of professional ▷ PU Decorative Panel Roll Forming Line | Sandwich Panel Line ◁ factory in China, we can supply different kinds of Decorative Panel Roll Forming Line for different Polyurethane Wall Cladding.

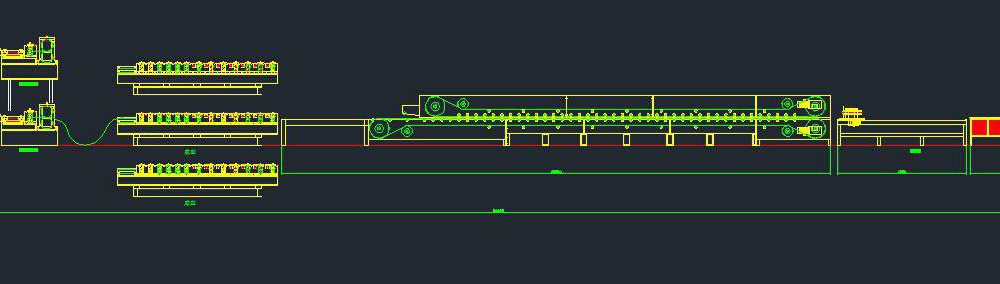

This PU foam siding wall cladding panel production line should be able to fulfill the material for composite sandwich panel continuous production of polyurethane. that is a continuous injection liquid raw material into the pressing of the upper and lower panels. Reaction, foaming, curing, forming in dual pedrail molding machine. Production the composite sandwich panel line with the state for the metal surface of rigid polyurethane sandwich panels. The PU sandwich panel has a function of sound insulation, heat insulation and prevent burn and use in wall panel, and so on.

It is not only suitable for the newly set up brick-concrete structure, framework structure, steel structure, lightweight buildings. but also perfect for the energy-saving reconstruction of the old buildings.